RAPPLON Flat Drive Belts

RAPPLON flat drive belts are endless drive belts made with a joint.

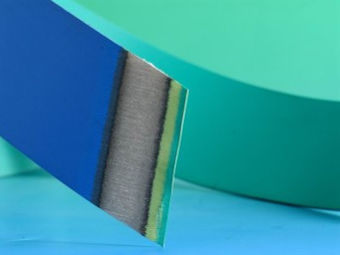

The base is made of nylon tension fabric or, in the new generation, a special fabric with thermoplastic properties. The fabric is coated with leather, natural rubber, elastomers or many thermoplastic surfaces, depending on the belt type. Seamless surfaces are also available for special uses.

They are supplied in many variants as open-ended belts in rolls or as endless belts exactly according to the customer's requirements.

Belts Construction

- Tensile member

- Bottom cover material

- Top cover material

Belts Fields of Use

High performance flat belts are designed to machine drives in all industries.

They are used mainly in machine tools, saws, grinders, pumps and also in agricultural, packaging, printing machines and many other machines and equipment.

Belts Characteristics

- High surface resistance

- Long service life

- Reduced stress and extended service life of bearings

- Shock and vibration damping

- High efficiency, energy saving

- Possibility of quick assembly, short downtimes

Belts Code Description

RAPPLON belt code always consists of a nomenclature and code of the belt.

Nomenclature

The nomenclature details the classification of the product according to the Ammeraal Beltech code system for RAPPLON belts.

GG E10.40 RRQ FG

| Code Part | Description |

|---|---|

| G |

Bottom side cover material (pulley side / running side) |

| G |

Top side cover material (back side / transport side) |

| E |

Tensile member material |

| 10 |

Tensile strength in N/mm at 1% elongation Tensile strength in 1/10 N/mm at 6% elongation for non-tensile members |

| .40 |

Total thickness in 1/10 mm |

| R |

Surface finish pulley side / running side (not mentioned for fabrics) |

| R |

Surface finish back side / transport side (not mentioned for fabrics) |

| Q |

Splicing / Joining (C = CLASSIC, Q = QUICKSPLICE) |

| FG |

Additional notes |

Belt Code

Every product has its own unique article code of 10 characters.

FBSF054624

| Code part | Description |

|---|---|

| FB |

Flat belt |

| SF |

Cover material bottom / top |

| 054624 |

Specific item number |

Belts Joints

RAPPLON belt joints can be made depending on the material from which the particular belt is made. You will find the exact information in the technical documentation of the selected belt.

| Joint Type | Description | Illustration |

|---|---|---|

CLASSIC |

This traditional splicing method involves skiving both ends of the belt and the application of an adhesive. The strength of a classic joint (wedge skive) is close to the belt strength thanks to skilled and experienced staff. |

|

QUICKSPLICE |

The QUICKSPLICE joining system (finger joint) guarantee quick and safe endless joining without the use of any adhesives. Resulting joints are highly flexible and durable. Advantages of QUICKSPLICE:

|

|

Belts Accessories

Guides

Guide profiles ensure direct belt guidance and prevent belt movement on the rollers. The result is a smooth guidance without a polygon effect, which is also suitable for higher speeds.

Profiles made of PVC, polyurethane or polyester are welded or glued to the bottom side of the conveyor belt.

The V-profile can also be used as a transverse carrier or side edge for transporting material.

The most common way of guiding the belt is a V-guide.

| Profile Type | Description | Illustration |

|---|---|---|

Full V-Profile |

The smooth, clean design of the wedge is less prone to contamination. |

|

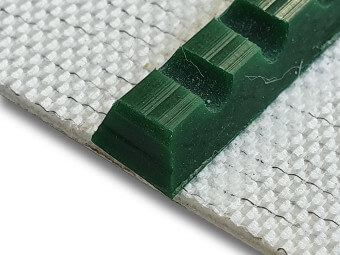

Lightweight V-Profile |

On the bottom side of the belt there is a wedge with pressed teeth, which allow easier bending and thus smaller cylinder diameters than solid wedges. |

|

In addition to the V-profiles, the guide profiles can also be square. However, their use is far from numerous. If you are interested in implementing square guide profiles, please contact us.

Additional Belts Modifications

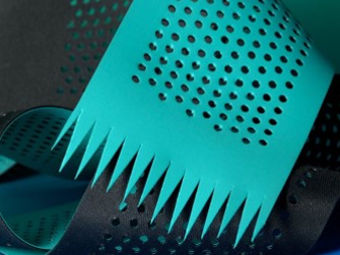

Punching

Punching of conveyor belts is performed for the transport of products using vacuum and for applications with photocell control.

Punching is performed on punching machines, which are able to produce punching in a precisely defined arrangement.

Documents for Download

Manufacturer Profile

Founded in 1950, Ammeraal Beltech is a global market leader in the design, manufacturing, fabrication and servicing of high-quality, high-performance process and conveyor belts, available today in 150 countries around the world. You can find their products almost in all industries. They employ over 2,750 people in the business.

They operate 10 manufacturing sites in Europe, the USA, Canada and Asia. They have sales and fabrication centres at over 80 sites worldwide and they have own subsidiaries in more than 25 countries.

Since 2012, our company has been an official distributor.