ZIPGUIDE Conveyor V-Belts

A modern alternative to standard belts. Greater reliability, longer service life, less maintenance. Based on the ZIPLINK principle.

For this article, we’ve chosen to highlight an interesting innovation in the field of conveyor belts. Originally developed for demanding applications in the ceramic tile industry, it offers benefits far beyond that sector.

We’re talking about ZIPGUIDE V-belts from Ammeraal Beltech. You might already be familiar with their flat conveyor belts based on the same principle – ZIPLINK. If not, keep reading – we’ll introduce them at the end of this article as well.

- An Innovation Beyond Ceramics

- A Unique Concept: How Does ZIPGUIDE Work?

- The Right Material = Protection for Belts and Products

- ZIPLINK Special Conveyor Belts

An Innovation Beyond Ceramics

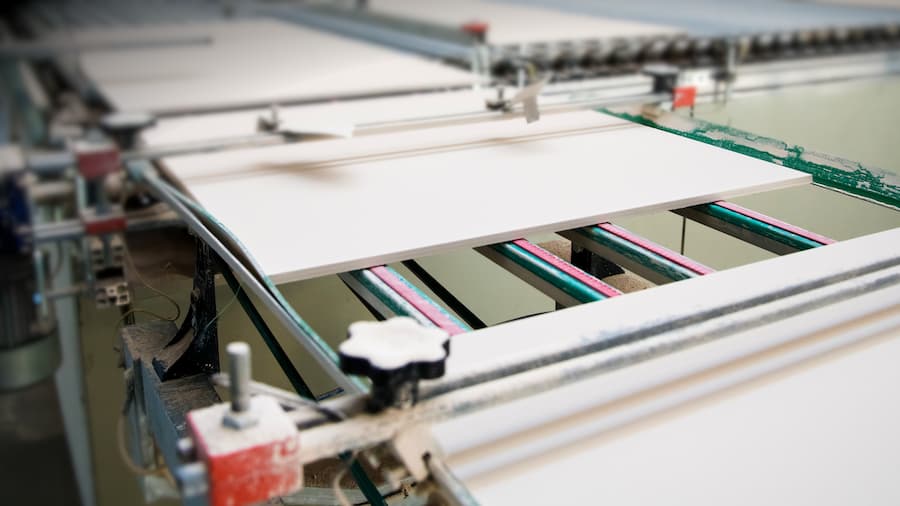

Tile production presents unique challenges. Chief among them is aggressive dust in the environment. Heavy, yet fragile tiles are moved along production lines by conveyor V-belts – and their surfaces suffer significant wear in the process. As a result, they need to be replaced frequently.

In most cases, this is done using thermoplastic belts that must be heat-welded with special tools. It’s a time-consuming process that requires qualified personnel, and the resulting welds are often prone to failure. This makes maintenance expensive – not just due to service costs and spare parts, but because of lost production time as well.

That’s why ZIPGUIDE belts were developed by Ammeraal Beltech – in collaboration with machine manufacturers and end users alike – to address these very issues. Their key advantages include quick and easy joining, high grip, and excellent wear resistance. They’re designed for conveying tiles throughout the ceramic production process – from kiln loading to handling and packaging.

Request ZIPGUIDE Conveyor V-Belts from TYMA CZ

You can request zip-style belts on the TYMA CZ website either through the general contact form or directly via the ZIPLINK flat belt e-shop category.

A Unique Concept: How Does ZIPGUIDE Work?

The most important advantage of ZIPGUIDE conveyor belts is their extremely quick and simple joining process – performed directly on the conveyor. According to the manufacturer, switching to ZIPGUIDE can reduce service effort and belt replacement time by more than 50%. How is that possible?

- The joint system creates no weak points.

- The connection is stable and secure.

- No special tools are required – and there's no need for external service.

- Easy installation minimizes the risk of errors.

Let’s take a look at how the replacement is done in practice. Here we go.

The Right Material = Protection for Belts and Products

ZIPGUIDE V-belts are not only designed to withstand premature wear – they’re also optimized to support every stage of the production process and provide maximum comfort for tiles or other products with specific requirements.

Key performance features:

-

High grip

Made from natural rubber or nitrile with excellent traction – even in humid conditions. -

Shape memory

Can stretch under tension and return to its original shape – no permanent deformation. -

Excellent durability and resistance

Resistant to abrasion, high temperatures – ideal for kiln transport – and a wide range of chemicals, including acids, oils, solvents, and alkalis.

A wide range of customization options is available – from top layer material and texture to guide profile – so the belts are perfectly matched to the application.

Overview of Available Top Cover Materials

| Material | Color | Properties | Surface Structure |

|---|---|---|---|

| Natural rubber | Red | Excellent grip | Smooth |

| Nitrile BX | Blue | High wear resistance | C37 Rough Top / Supergrip |

| Natural rubber | Natural | Excellent grip | C37 Rough Top / Supergrip |

| Nitrile | Brown | High grip / High wear resistance | C37 Rough Top / Supergrip |

ZIPGUIDE Special Open-Ended V-Belts in the TYMA CZ Eshop

ZIPLINK Special Conveyor Belts

Just like ZIPGUIDE belts, ZIPLINK conveyor belts from Ammeraal Beltech are designed for quick, easy replacement – right on the machine. No presses, no welders, no special tools, and no training required.

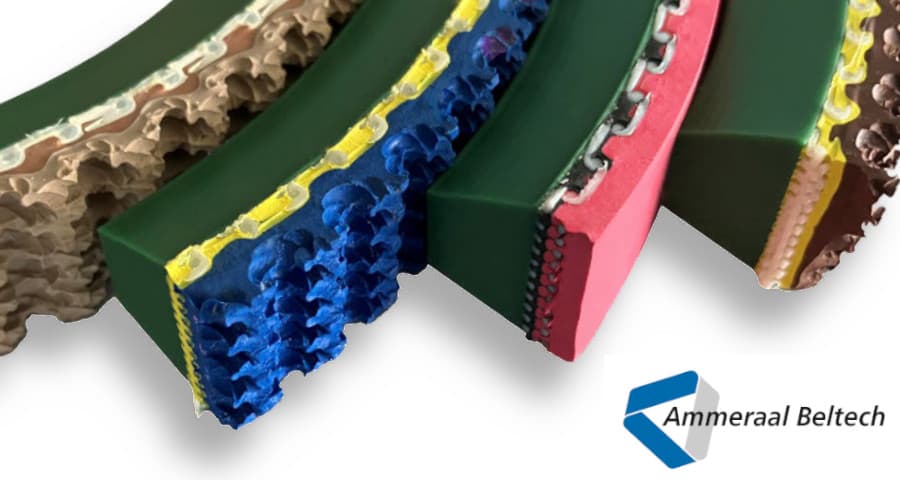

Each ZIPLINK belt consists of a functional top layer and – just like the belts described above – a unique spiral bottom layer. The top layer is selected for the specific application, while the spiral structure underneath allows for easy joining into an endless belt of any length.

The belts are uniform along their full length – with no splice section or seam. If the belt ever needs repair, you can simply replace the affected section.

A Truly Universal Solution

ZIPLINK belts are used to transport materials across a wide range of industrial sectors. They’re especially common in the food, paper, packaging, wood, tobacco, glass, ceramics, automotive, and chemical industries.

You’ll also find them in agriculture, tire production, and intralogistics systems – such as airport conveyors or warehouse sorters.

The wide range of applications calls for a broad selection of top-layer materials and textures – whether the goal is easy product release, extra grip on inclines, or controlled adhesion during processing.

That’s why the ZIPLINK product range includes dozens of top layer materials and surface textures. The most common ones are:

- Cotton/Felt

- Carboxylated Nitrile

- Nitrile

- Natural Rubber

- SBR

- Silam

- Teflon

For stable tracking even at higher speeds, V-guides can be welded or glued to the belt. Plastic profiles can also serve as cleats for product separation or incline transport.