HTD 8M-912-50 CONTI SYNCHROFORCE ADVANCE PRO (EPDM, Formerly CXA)

Timing Belt

Price without VAT: 122.07€

Price including VAT: 147.70€ with VAT

Catalogue price excluding VAT:

124.55€

The product is custom-made from a semi-finished product. It cannot be returned or replaced. In accordance with the provisions of § 1837, letter d) of Act No. 89/2012 Coll., the Civil Code (hereinafter referred to as the “Civil Code”), the consumer may not withdraw from a contract of purchase in the sense of the provisions of § 2079 et seq. of the Civil Code, if it concerns a contract on delivery of goods that have been adjusted by request of the consumer or for the consumer, concluded by means of remote communication.

At supplier,

we usually ship within 2 weeks Usual time this product is ready for shipping. Actual availability may vary due to unforeseen circumstances in exceptional cases.

We usually made this product from a semi-finished product during the first working day after the order.

Specifications

Pitch length of the belt. It is commonly denoted as Lp or Lp.

In the TYMA Product Catalogues you can find this material also described with the abbreviation EPDM.

Belt Description

HTD 8M-912-50 CONTI SYNCHROFORCE ADVANCE PRO (EPDM, Formerly CXA) is a heavy-duty timing belt designed to deliver top performance in transmitting the highest torque. It is antistatic in compliance with ISO 9563.

The CONTI SYNCHROFORCE ADVANCE PRO belts are made of an aramid-fiber reinforced EPDM rubber, providing exceptional temperature resistance, with an aramid-cord tension member. They offer a significantly extended service life compared to the previous chloroprene generation (in the ContiTech portfolio, they replace the former CONTI SYNCHROFORCE CXA series).

Construction

- Protective low-friction polyamide fabric

- Teeth made of aramid-fiber reinforced EPDM rubber

- Aramid-cord tension member

- Backing made of aramid-fiber reinforced EPDM rubber

Typical Applications

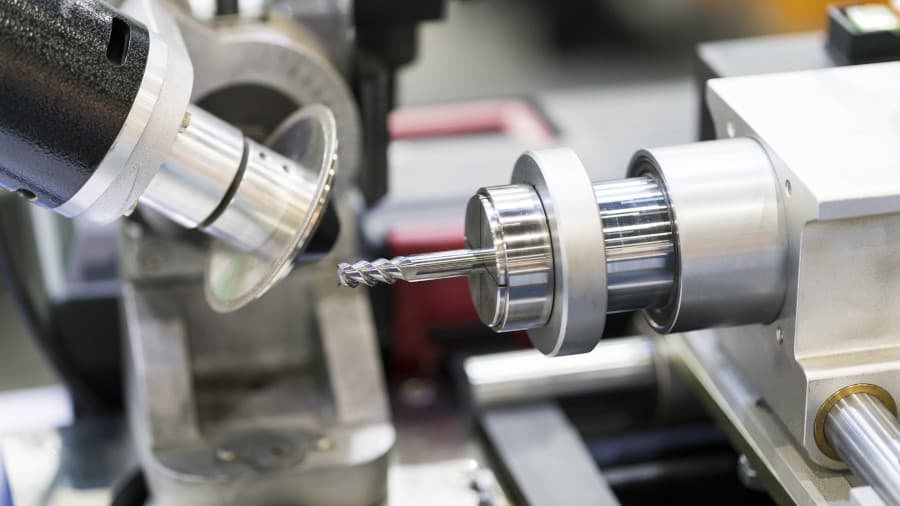

CONTI SYNCHROFORCE ADVANCE PRO timing belts in the H8M profile are intended for heavily loaded industrial drives with the highest torque requirements and high dynamic forces.

They are typically used in highly stressed power transmissions in machine tools, presses, heavy conveyor systems, printing and textile lines, automated production systems, and other machinery with extreme performance demands.

Thanks to the improved temperature resistance provided by the advanced EPDM compound, additional application possibilities open up.

Properties

- High power transmission capability

- Long service life – significantly extended service cycle compared to the previous chloroprene (CR) generation

- Conditionally oil-resistant

- Suitable for use in tropical environments

- Temperature resistance from −40 °C to +120 °C

- Chlorine-free, PFAS-free, with reduced levels of PAHs, halogens, and solvents

- Maintenance-free

- Antistatic properties according to ISO 9563

Certificates

- Factory Electrical Conductivity Certificate of Belts According to ISO 1813 and ISO 9563 (pdf, 104.90 kB)

- ContiTech Explanation of ATEX Certification (pdf, 11.96 kB)

Notice

General factory certificates are not sufficient for belts used in potentially explosive atmospheres.

If a test report according to ISO 1813 and ISO 9563 is required for the application, it is necessary to inform us of the request for delivery of belts including the certificate when ordering them (when ordering belts via Eshop, please write this request in the "Note" field before by sending the order). The certificate is issued by ContiTech after the test in the production plant.

Documents for Download

Questions about This Product?

Don’t hesitate to contact us – our specialists will be happy to help with any questions about this belt.

Belt Manufacturer Profile

Continental ContiTech is a global technology company focused on the development and manufacture of industrial solutions for power transmission, material handling, and other key areas of modern industry. It is an important partner across a wide range of industrial sectors – from the automotive industry and rail vehicles to aviation and industrial machinery.

ContiTech is a part of the Continental AG group, which, with dozens of production sites and tens of thousands of employees worldwide, ranks among the largest European industrial companies.

We are an authorized distributor and a preferred partner of Continental ContiTech Industrial Solutions within the Partner of Choice program.

Related Articles

ContiTech Timing Belts: the New EPDM Generation Is Coming

Key features will improve significantly, starting with the standard belts. Under CONTINUITY, the belts will be renamed and carry new markings.

Continental CONTINUITY

The new ContiTech industrial belt names will replace many of the well-known and long-established product line names on the market.