Drive Calculation and Optimization

We provide design and calculation of V-belt, timing belt, and flat belt drives, as well as conveyor belts, chain drives, shaft couplings, and other drive components.

Our Services in Drive Calculation and Optimization:

- Design and Calculation of Drive Belts

- Drive Optimization and Energy Saving Calculation

- Design and Calculation of Linear Applications

- Design of Pulleys and Couplings in CAD Software

- Belt Pre-Tension Calculation, Alignment Check, and Pre-Tension Check During Assembly

- Drive or Coupling Calculation Form

Design and Calculation of Drive Belts

Based on your specifications, we will calculate the drive and select the most suitable option.

In more complex cases, we work directly with the manufacturer's technical department. The result is a calculation report in PDF format.

You can also perform the basic calculation yourself using the Conti Professional software. More information can be found in the section Useful Applications and Online Tools.

If required, we will send you technical data and dimension sheets. Many technical catalogs can also be downloaded in the sections Downloads or Technical Information.

Belt calculations and consultancy are provided free of charge.

Transmission Optimization and Energy Saving Calculation

We will analyze the energy efficiency of the drive and calculate the possible energy saving using the Conti Professional calculation software.

The calculation accounts for the key factors influencing belt drive efficiency: the type of drive, the number of operating hours, maintenance practices, and especially the condition of the belts (new, used, worn). The result is a calculation report including energy efficiency data.

As part of our services, we will suggest ways to increase efficiency and energy savings.

More Information about Increasing Belt Drive Efficiency and Energy Saving

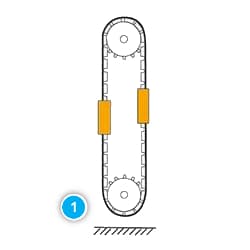

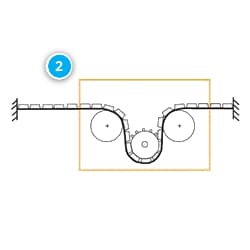

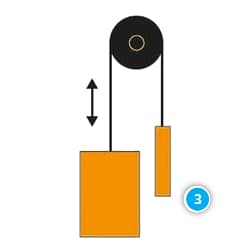

Design and Calculation of Linear Applications

Using the Conti Professional calculation software, we will design and calculate the belts for linear applications.

The software supports both types of belt use – endless belts for drives and open-ended belts for linear and lifting applications.

We will propose one or more design variants. The calculation includes all necessary application data and the safety factor.

- Double-sided lift drive

- Linear carriage

- Flat belt – traction drive

Design of Pulleys and Couplings in CAD Software

We provide CAD-based modification proposals for pulleys, sprockets, shaft couplings, and other components.

According to your requirements, we will prepare a technical drawing of the required or already supplied component in Autodesk Inventor.

CAD drawings of pulleys, clamping bushings and other standardized parts can also be found at TraceParts, linked from the section CAD drawings on this website.

Belt Pre-Tension Calculation, Alignment Check, and Pre-Tension Check During Assembly

As part of our services, we will check the belt drive pre-tension, calculate the required pre-tension, and the bearing load.

If you need to reduce the pre-tension or bearing load, we will suggest optimization or drive modification.

We can also assist you during assembly and check alignment and pre-tension using laser instruments.

These services are provided free of charge as part of supplied drive systems.