Bando BANFLEX – V-Belts for CNC Drives

Stable power transmission without vibration, even at high speeds. Lightweight and compact design. Resistance to harsh operating conditions.

In this article, we’re kicking off a special topic: BANFLEX and BANFLEX SCRUM endless polyurethane V-belts engineered for high-speed and precision drive applications.

We’ve already touched on their key advantages – but what makes their construction unique? You’ll also learn what to watch out for when selecting the right belt. We’ll share practical tips for drive design – and even reveal an unexpected link to the world of sports.

- BANFLEX. SCRUM. Fast, Quiet, and Compact

- Not Only Rugby Has Its Scrum – Belts Do Too

- Construction

- Belt Line-Up: Performance Depends on the Right Formation

- Belt Availability: Factory-Made vs. Sleeve-Cut

BANFLEX. SCRUM. Fast, Quiet, and Compact Belts

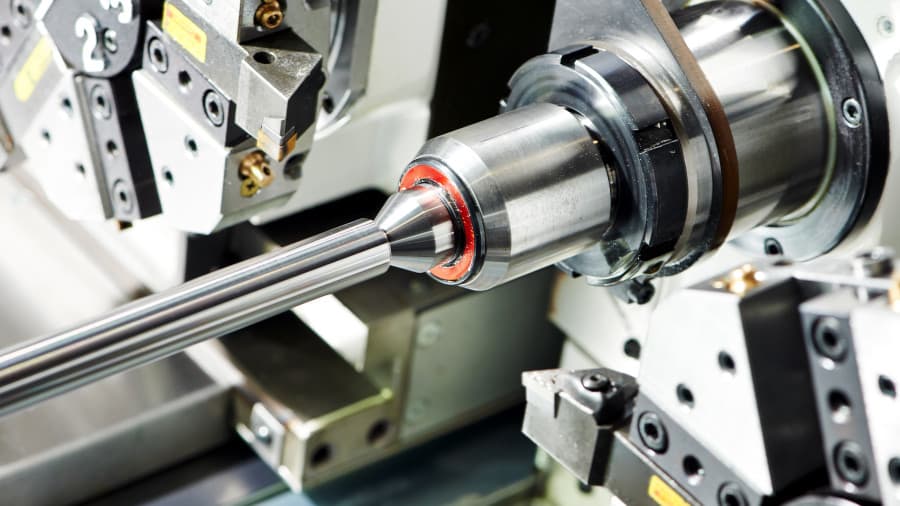

Polyurethane V-belts with a 60° profile angle from the Japanese manufacturer Bando offer a specialized solution for high-speed, precision drive applications with high power transmission. They deliver exceptionally smooth, low-vibration performance and excellent stability even in vertical shaft drives, while allowing for a significant reduction in overall drive size.

As a result, BANFLEX and BANFLEX SCRUM belts are ideally suited for use in lathes, milling, grinding, and engraving machines – collectively referred to as CNC machines – particularly for high-speed spindle drives (above 10,000 rpm). Thanks to their compatibility with small pulley diameters, they are also suitable for ATC drives as well as for cooling pumps, fans, and other auxiliary drives.

Their smooth and precise running characteristics also make them ideal for measuring instruments and various types of testing and laboratory equipment.

Special BANFLEX & BANFLEX SCRUM V-Belts in the TYMA CZ Eshop

We are an authorized regional Bando distributor. Selected BANFLEX belt sizes are held in stock. Once ordered, they are dispatched no later than the next working day.

Key properties common to single-profile BANFLEX and banded multi-profile BANFLEX SCRUM belts:

High-Speed Power Transmission with Smooth Running

The high accuracy of the belt cross-section and effective length, combined with consistent groove seating, ensures exceptionally smooth power transmission at high speeds – almost like flat belts.

While conventional V-belts are typically limited to 30–40 m/s, BANFLEX belts are engineered for speeds of up to 60 m/s.

Lightweight and Compact Drive Design

Thanks to the 60° profile angle, which provides uniform pressure distribution along the flanks, the use of flexible polyurethane, and the ribbed back that reduces bending stress and prevents localized heating, BANFLEX belts can operate reliably with small pulley diameters.

This enables high transmission ratios and drive systems with minimal size and weight. For example, a two-stage drive using standard V-belts can often be replaced with a single-stage drive using BANFLEX belts.

Resistance to Operating Conditions and Long Service Life

By using polyurethane instead of conventional rubber, BANFLEX belts offer outstanding resistance to oils, ozone, UV radiation, weathering, and wear.

Polyurethane also provides excellent abrasion resistance and a high coefficient of friction, ensuring stable power transmission without slippage and prolonged belt life. Temperature resistance is guaranteed from −30 °C to +60 °C.

Properties specific to banded BANFLEX SCRUM belts:

Stable Power Transmission without Vibration

The individual belt ridges are permanently bonded into a single band, which effectively eliminates vibration. The result is stable power transmission without belt turnover and without the risk of jumping off the pulley.

Ideal for Vertical Shaft Drives

The fixed connection between ridges prevents contact or misalignment between individual belts. Even with a vertical shaft layout, deep-groove pulleys are generally not required.

In the following sections, we’ll take a closer look at the belt construction and present the available profiles and dimensions. We’ll also provide recommendations for drive design and practical tips for ordering from the TYMA CZ online shop. But first, let’s clarify the naming conventions.

Not Only Rugby Has Its Scrum – Belts Do Too

Naming conventions: what do SCRUM, BANFLESCRUM, and COMBO actually mean?

The distinction is simple. Single-profile belts are marketed under the name BANFLEX.

The banded versions are designated as BANFLEX SCRUM. Scrum? Just as in rugby, where the scrum is a tightly packed formation of players, the SCRUM designation reflects the permanent bonding of multiple belt profiles into a single unit to maximize stability and power transmission.

For completeness, note that the manufacturer also uses the name BANFLESCRUM in some of its technical materials and BANFLEX COMBO on the US market.

BANFLEX SCRUM Construction

The 60° profile angle of BANFLEX belts is not just a design difference from standard V-belts with a 40° angle. It is a critical parameter that enables higher power transmission, reduced vibration, and a more compact drive design.

This specific geometry requires the use of special pulleys with the same 60° angle. Standard V-belt pulleys are not compatible under any circumstances.

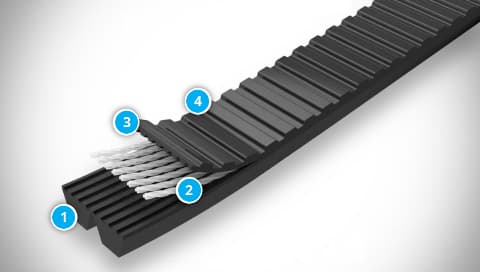

Let’s take a closer look at the belt construction:

-

Polyurethane body

The polyurethane compound delivers excellent abrasion resistance and a high coefficient of friction, ensuring precise power transmission. The 60° profile angle distributes load evenly across the flanks, contributing to high efficiency. -

Polyester tensile cords

These cords carry the tensile load. They provide high tensile strength, very low elongation, and excellent resistance to flex fatigue. -

Reinforcing fabric (SCRUM versions only)

This layer increases transverse rigidity in multi-ridge belts, ensuring exact belt tracking in the pulley. -

Ribbed back

The back-side ribs reduce bending stress and eliminate local heat buildup as the belt passes over the pulley. This enables the use of small pulley diameters without shortening belt service life.

To maintain optimal dynamic performance, a lubricating additive is incorporated into the belt. Due to temperature fluctuations, this additive may occasionally appear as a white film or a slightly moist surface. During operation, it is reabsorbed into the belt material. This is a normal characteristic and does not affect belt performance or service life.

Belt Profiles and Lengths

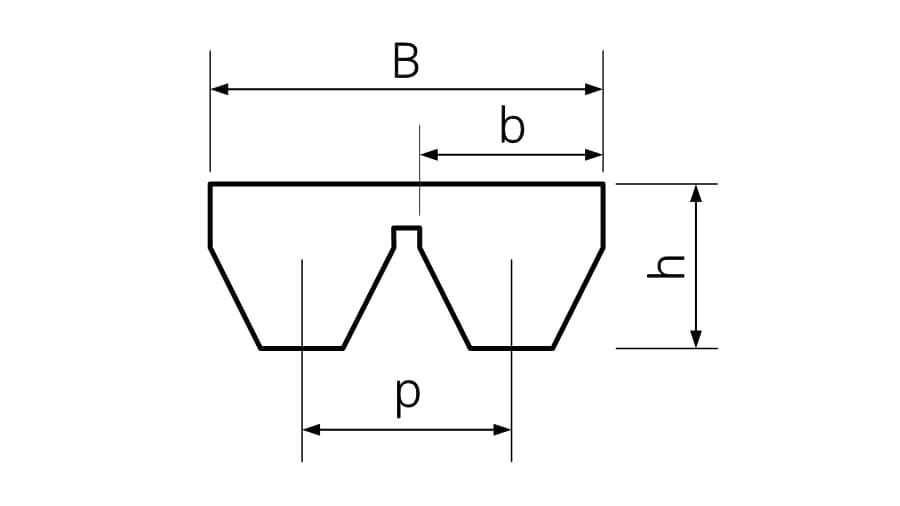

Both BANFLEX (single-profile) and BANFLEX SCRUM (banded) belts are produced in profiles with groove widths of 3, 5, 7, and 11 mm. The designation MS identifies a banded belt (S = SCRUM).

The diagram shows the dimensional characteristics of multi-ridge BANFLEX SCRUM belts.

The table below provides an overview of the profiles currently included in Bando’s production program, together with the available outer lengths.

Dimensions of manufactured profiles and available outer lengths:

| Profile | Pitch p [mm] | Groove Width b [mm] | Belt Height h [mm] | Length Range La [mm] |

|---|---|---|---|---|

| 3M | - | 3.00 | 2.10 | 180–750 |

| 5M | - | 5.00 | 3.30 | 280–1,850 |

| 7M | - | 7.00 | 5.30 | 500–2,300 |

| 11M | - | 11.00 | 6.90 | 710–2,300 |

| 3MS | 3.35 | 3.00 | 2.10 | 580–615 |

| 5MS | 5.30 | 5.00 | 3.30 | 280–1,850 |

| 7MS | 8.50 | 7.00 | 5.30 | 450–2,300 |

| 11MS | 13.20 | 11.00 | 7.00 | 710–2,300 |

BANFLEX Belts in the TYMA CZ Eshop

BANFLEX SCRUM Belts in the TYMA CZ Eshop

BANFLEX SCRUM Line-Up: Performance Depends on the Right Formation

BANFLEX SCRUM belts are available as standard in two-ridge or three-ridge designs. But how do you correctly assemble a multi-ridge configuration on multi-groove pulleys?

When more than three ridges are required, the set is composed of multiple two- and three-ridge bands in appropriate combinations, as shown in the table below. In a single formation, the recommended maximum number of ridges is 12.

Manufacturer-recommended formations for multi-ridge BANFLEX SCRUM belts:

| Number of Ridges | Combination |

|---|---|

| 2 | 2 |

| 3 | 3 |

| 4 | 2+2 |

| 5 | 2+3 |

| 6 | 3+3 |

| 7 | 2+3+2 |

| 8 | 3+2+3 |

| 9 | 3+3+3 |

| 10 | 2+3+3+2 |

| 12 | 3+3+3+3 |

BANFLEX SCRUM Belts in the TYMA CZ Eshop

BANFLEX Belt Availability: Factory-Made vs. Sleeve-Cut

Single-profile BANFLEX belts in profiles 5M, 7M, and 11M are available in two manufacturing variants under the same designation. In the e-shop, these variants are clearly indicated in the product name as factory-made or sleeve-cut.

Because these variants are produced using different processes, their dimensions are not identical. When installing belts in a multi-belt drive, all belts in the set must be of the same type. Mixing variants results in uneven belt tension, leading to increased wear, vibration, overheating, and premature failure.

Factory-Made Belts

These belts are produced as finished single-profile belts and are designed specifically for use as individual belts – including when installed in a set on multi-groove pulleys.

Sleeve-Cut Belts

These belts are cut from BANFLEX SCRUM sleeves. Because multi-ridge belts are structurally slightly thicker than single belts, sleeve-cut belts differ in their length and will alter the shaft center distance when installed.

To be specific, the table below shows the expected change in center distance when switching from factory-made BANFLEX belts to sleeve-cut belts (made from BANFLEX SCRUM sleeves), based on manufacturer data.

Change in center distance when switching from factory-made belts to sleeve-cut belts:

| Variant Transition | Center Distance Reduction [mm] |

|---|---|

| 5M → 5MS | 3–5 |

| 7M → 7MS | 5–6 |

| 11M → 11MS | 6–8 |

This dimensional difference is intentional and part of the design. It does not affect power transmission capability, but it does change the belt length and shaft center distance.

Availability from TYMA CZ

Due to the wide range of profiles and the two manufacturing variants, factory-made single belts are usually not stocked and may require longer lead times.

However, most required sleeves are regularly stocked, allowing sleeve-cut belts to be dispatched no later than the next working day. These belts are slightly more expensive due to the cutting process.

BANFLEX Belts in the TYMA CZ Eshop

BANFLEX SCRUM Belts in the TYMA CZ Eshop

Not sure which belt is the right choice? Contact us and we’ll be happy to recommend the optimal solution for your machine.