Bando BANFLEX SCRUM Special Banded V-Belts

Bando BANFLEX SCRUM special wedge polyurethane banded V-belts with a wedge angle of 60° are designed for high-speed transmission with smooth and quiet operation and very low vibration.

The belts are made of highly durable polyurethane and special polyester tension member. The diagonally grooved back optimizes flexibility. These grooves are reinforced with a synthetic fiber canvas.

Belts Construction

- Polyurethane belt structure

- Polyester tension member

- Synthetic fiber reinforcing canvas

- Ribbed belt backing

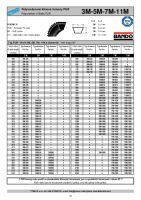

Belt Dimensions

- B

- Total width

- p

- Pitch

- b

- Rib width

- h

- Belt height

| Profile | Pitch p [mm] | Rib width b [mm] | Belt height h [mm] |

|---|---|---|---|

| 3MS | 3.35 | 3.00 | 2.10 |

| 5MS | 5.30 | 5.00 | 3.30 |

| 7MS | 8.50 | 7.00 | 5.30 |

| 11MS | 13.20 | 11.00 | 7.00 |

The total width

Belts Fields of Use

Bando BANFLEX SCRUM special banded V-belts are primarily used as drive belts in high-speed machines and in applications that require smooth operation and high precision.

They are typically used in applications such as machine tools, woodworking machines, as well as in other equipment.

Belts Characteristics

- Power transmission at high speeds (up to 60 m/s)

- Low vibrations (even at high speeds)

- High efficiency

- High durability and long service life

- Temperature resistance from −30 °C to +60 °C

- Resistance to oils

- Resistance to ozone

- Small pulley diameter, compact drive dimensions

Belts Code Description

Example:

3-11MS-1500 La BANFLEX SCRUM

| Code Part | Description |

|---|---|

| 3 |

3-banded |

| 11MS |

Profile |

| 1500 La |

Outside length in mm |

| BANFLEX SCRUM |

Type of belt |

Caution

Bando BANFLEX SCRUM belts cannot be used with standard V-belt pulleys; special pulleys with a 60° angle must be used.

Documents for Download

Belt Manufacturer Profile

Japanese company Bando has been a pioneer in the non-tire rubber and plastics industries since their founding in 1906, responding to customer needs with new technology and product development.

Over the years Bando have expanded upon their core business to meet the ever-changing needs of the times, and they now produce a wide range of products. They now serve their customers worldwide from more than 10 countries in Asia, North America and Europe.