EAGLE 5M Polyurethane Open-Ended Timing Belts

Polyurethane self-guiding open-ended EAGLE timing belts with H.O.T. 5M profile are made from thermoplastic polyurethane, which has high dimensional stability and wear resistance, and steel tensile fiber, in special cases aramid or stainless steel tensile fiber.

The open-ended belts can be welded into endless belts.

Products are sorted by name in ascending order.

EAGLE 5M-12.5 PAZ (Black)

Open-Ended Timing Belt

In Stock We update the stock availability information every 2 hours.

The goods we have in stock are usually ready for shipping or personal collection no later than the next working day. In case of personal collection, please do not come to pick the goods up before we contact you that the goods are ready.

24.54€ excl. VAT

29.69€ incl. VAT

EAGLE 5M-25 PAZ (Black)

Open-Ended Timing Belt

At Supplier

Within 3 Weeks Usual time this product is ready for shipping. Actual availability may vary due to unforeseen circumstances in exceptional cases.

We usually made this product from a semi-finished product during the first working day after the order.

50.13€ excl. VAT

60.65€ incl. VAT

Products are sorted by name in ascending order.

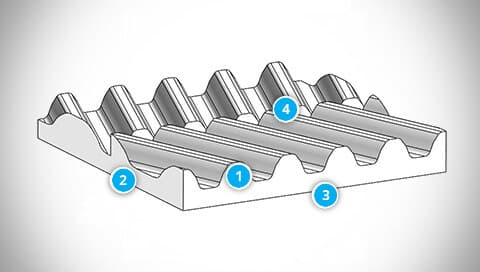

Belts Construction

- Polyurethane helical offset teeth

- Steel tension member

- Polyurethane back

- Nylon covering fabric on the teeth

Belts Fields of Use

EAGLE 5M polyurethane timing belts are used in special applications where a self-guiding belt that is not guided in the guide line or by pulley flanges is required. At the same time, these belts have significantly lower noise and vibration than other profiles with straight-cut teeth.

Belts are used in high-precision positioning and sorting applications, single-purpose machines, woodworking, packaging and food processing machines.

Belts Characteristics

- High transmitted power and long life

- Resistant to oil, petrol, benzene, UV radiation and ozone

- Abrasion resistance

- Temperature resistance, depending on the method of use, from −30 °C to +80 °C

- Up to 19 dB noise reduction compared to straight tooth timing belts

- Arrow gearing has self-guiding capabilities, no belt guidance is necessary

- Very quiet operation and extremely low vibration

- Aging and ozone resistance

Belts Code Description

Example:

EAGLE 5M-25 PAZ (Black)

| Code Part | Description |

|---|---|

| EAGLE |

Type of polyurethane helical offset tooth timing belts (SILENTSYNC) |

| 5M |

Belt profile and tooth pitch in mm |

| 25 |

Belt width in mm |

| PAZ |

Belt surface layer |

| Black |

Belt color |

Belts Colors

Polyurethane self-guiding open-ended EAGLE timing belts are produced as standard in white with gray fabric on the teeth (PAZ). The exception is the belts in the EAGLE 5M profile, which are produced in black with black fabric on the teeth (PAZ).

Nylon fabric on the teeth (PAZ) is automatically standard on EAGLE helical offset tooth timing belts. It serves to protect the teeth and reduce the coefficient of friction.

Documents for Download

Dimensions and Parameters of Polyurethane Open-Ended Timing Belts

TYMA CZ Data Sheets

Czech and English (PDF 903.91 kB)

Belt Manufacturer Profile

Elatech, a Company of the SIT S.p.A. Group, is fully dedicated to the research, development and manufacture of polyurethane belts for industrial applications.

SIT belongs to a large industrial group that dates as far back as 1838. Today, thanks to over 50 years of specific experience in power transmission and a close-knit team of highly qualified professionals, the Group engages in constant technological innovation in order to offer the best application solutions in mechanical power drives.

Their research and development are based in Italy, as well as the group’s main production and logistics centre. The global contribution given to their customers success is made through their subsidiaries in three continents, which are based in Germany, France, Switzerland, Spain, United States, China and India.