STD Polyurethane Open-Ended Timing Belts

Polyurethane open-ended timing belts in STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds. profile are made of thermoplastic polyurethane, which has high dimensional stability and wear resistance, and steel tensile fiber, in special cases aramid or stainless steel.

The open-ended belts can be welded into endless belts.

STD S3M

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds. polyurethane timing belts

STD S5M

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds. polyurethane timing belts

STD S8M

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds. polyurethane timing belts

STD S14M

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds. polyurethane timing belts

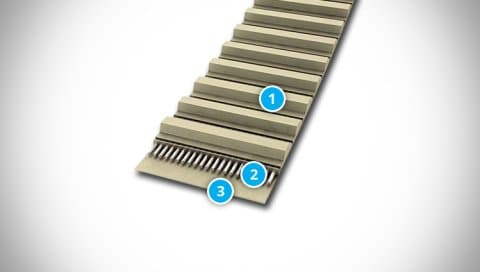

Belts Construction

- Polyurethane teeth

- Steel cord tension member

- Polyurethane backing

Belts Fields of Use

Polyurethane timing belts are used in all areas, from miniature drives, high-precision positioning and sorting mechanisms, small handheld machines to high-performance drives for building and woodworking machines.

Belts Characteristics

- High transmission power and long life

- Resistant to oil, fuel, benzol, UV radiation and ozone

- Wear-resistant

- Temperature range, depending on application, from −30 °C to +80 °C

- Maintenance-free

Belts Code Description

Example:

STD S8M - 20 HP PAZ CONTI SYNCHRODRIVE (Black)

| Code Part | Description |

|---|---|

| STDSuper Torque Drive The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds. |

Profile |

| S8M |

Tooth pitch in mm |

| 20 |

Belt width in mm |

| HPHigh Power | |

| PAZPolyAmid Zahne – Nylon Fabric on Teeth. Thus sometimes also mentioned as NFT. | |

| CONTI SYNCHRODRIVE (Black) |

Type of belt |

Belts Versions

| Type | Description |

|---|---|

| HPHigh Power | High power tensile-strength |

| XHPeXtremely High Power | Very high power tensile-strength |

| XHPeXtremely High PowerII | Extremely high power tensile-strength |

| HSHigh Stiffness | High stiffness of tension member |

| HSHigh StiffnessII | Very high stiffness of tension member |

| HFHigh Flexibility | High flexibility |

| HPHigh Power-Niro | Stainless steel tension fibers |

| Aramid | Aramid tension fibers |

Optional Belt Surface Layers

The choice of the surface layer depends on the type of machine, the ambient temperature, the size of the pulleys, etc. Specifying the surface layer is determined by the material and the thickness of the layer.

| Layer Name | Material | Layer Illustration |

|---|---|---|

| PAZPolyAmid Zahne – Nylon Fabric on Teeth. Thus sometimes also mentioned as NFT. (NFTNylon Fabric on Teeth. Also mentioned as PAZ – PolyAmid Zahne.) - nylon fabric on teeth Low coefficient of friction |

Nylon |  |

| PARPolyAmid Rücken – Nylon Fabric on Back. Thus sometimes also mentioned as NFB. (NFBNylon Fabric on Back. Also mentioned as PAR – PolyAmid Rücken.) - nylon fabric on back Surface protection |

Nylon |  |

| PAZPolyAmid Zahne – Nylon Fabric on Teeth. Thus sometimes also mentioned as NFT. + PARPolyAmid Rücken – Nylon Fabric on Back. Thus sometimes also mentioned as NFB. (NFTNylon Fabric on Teeth. Also mentioned as PAZ – PolyAmid Zahne. + NFBNylon Fabric on Back. Also mentioned as PAR – PolyAmid Rücken.) - fabric on teeth and back Low coefficient of friction and surface protection |

Nylon |  |

The fabric on teeth and back can be combined with all other layers. A complete range of belt surface layers

Belts Colors

The most common color of open-ended polyurethane belts with steel tension member is white. ContiTech also offers these belts in black.

Basic HPHigh Power belts have the same characteristics as white belts. The color is the only difference. Black color is required for some applications due to its design or greater light fastness. White color changes over time - it turns yellow. In addition, any spots are more noticeable on white.

Reinforced types XHPeXtremely High Power, XHPeXtremely High PowerII, HSHigh Stiffness and HSHigh StiffnessII are mostly produced by ContiTech only in black.

Documents for Download

Dimensions and Parameters of Polyurethane Open-Ended Timing Belts

TYMA CZ Data Sheets

Czech and English (PDF 903.91 kB)

Calculation of STD S3M, S5M and S8M CONTI SYNCHRODRIVE Timing Belt Drives

ContiTech Data Sheets

Czech and English (PDF 331.14 kB)