CONTI V TORQUE TEAM Is Here. New Names for ContiTech Banded V-Belts

CONTI-V MULTIBELT? A synonym for quality banded V-belts is now available under a new name and imprint design. Get to know them.

First things first: while the belts are already being produced with the new name and updated imprint design, nothing has changed in terms of technical specifications or performance. The materials remain the same — there’s no need to adjust machine design, installation, belt tensioning, or operating conditions.

CONTI V TORQUE TEAM Banded V-Belts in the TYMA CZ Eshop

Easily order the new belts, matching pulleys, and other drive components. Standard versions come with 2 to 6 ribs. For wider belts, rib combinations apply (e.g. 8 = 4 × 2 or 2 × 4, etc.).

So why the change? It’s all part of ContiTech’s global portfolio harmonization. More details in our earlier article: Continental CONTINUITY.

CONTINUITY!

The structure of ContiTech’s banded belt portfolio clearly mirrors that of single V-belts – after all, banded belts are essentially multiple single belts joined together into one wide unit.

The range is divided into two main branches, with categories reflecting different performance levels and application demands.

CONTI-V MULTIBELT → CONTI V TORQUE TEAM

Wrapped belts in narrow-section profiles: SPZ, SPA, SPB, and SPC according to ISO 4184 (DIN 7753), 3V/9J, 5V/15J, and 8V/25J according to RMA/MPTA IP-22. Standard versions in classic profiles according to ISO 4184 (DIN 2215) remain available as well.

| Old Product Name | New Product Name |

|---|---|

| CONTI-V MULTIBELT | CONTI V TORQUE TEAM |

| CONTI-V MULTIBELT ADVANCE | CONTI V TORQUE TEAM ADVANCE |

| CONTI-V MULTIBELT POWER | CONTI V TORQUE TEAM SUPREME |

CONTI-V MULTIBELT FO → CONTI VX TORQUE TEAM

Raw-edge, toothed belts. Currently available in narrow-section profiles: XPB according to ISO 4184 (DIN 7753), or 3VX/9JX and 5VX/15JX according to RMA/MPTA IP-22.

| Old Product Name | New Product Name |

|---|---|

| CONTI-V MULTIBELT FO | CONTI VX TORQUE TEAM |

| CONTI-V MULTIBELT FO ADVANCE | CONTI VX TORQUE TEAM ADVANCE |

We’ll now take a closer look at the reinforced category of banded V-belts designed for demanding applications – CONTI V TORQUE TEAM ADVANCE (formerly CONTI-V MULTIBELT ADVANCE).

If your current belts are being pushed to their limits, this one’s worth reading.

Reliable Performance: CONTI V TORQUE TEAM ADVANCE

These universal banded V-belts – previously known as CONTI-V MULTIBELT ADVANCE – belong to the medium power performance category. They are ideal for drives with irregular or shock loads, and larger center distances. Thanks to their construction, they ensure reliable operation even without the need for retensioning.

With their robust and durable design, they’re built for applications where the belt drive is expected to deliver long-term, high-performance in demanding operating conditions – such as crushing, grinding, mixing, sanding, cutting, pressing, and pumping.

Other key advantages include exceptionally smooth operation, maintenance-free performance, and electrical conductivity in accordance with ISO 1813. Operating temperatures range from −30 °C to +80 °C.

These belts offer a well-balanced solution with an attractive price-to-performance ratio, backed by product quality worthy of German engineering.

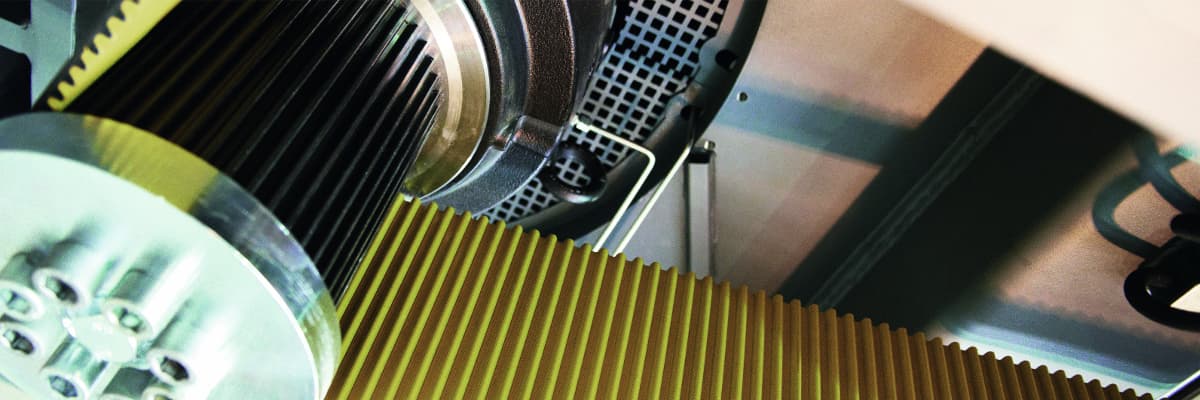

Belt Construction

Key differences of CONTI V TORQUE TEAM ADVANCE compared to the basic CONTI V TORQUE TEAM range:

- Reinforced polyester tension member → significantly reduced elongation under load

- Fiber-reinforced synthetic-rubber base body → improved support for tension cords

- Double fabric jacket → increased abrasion resistance, even in dusty environments

- Fiber-reinforced synthetic-rubber backing → enhanced dimensional stability and resistance to deformation

These enhancements enable higher power transmission and longer service life, along with greater shock load resistance and improved transverse rigidity. As a bonus, the belts also offer increased temperature and chemical resistance.

Profiles and Sizes of CONTI V TORQUE TEAM ADVANCE Belts

The belts are currently manufactured in European narrow-section profiles SPB and SPC according to ISO 4184 (DIN 7753), as well as US narrow-section profiles 5V/15J and 8V/25J according to RMA/MPTA IP-22.

| Profile | Length Range |

|---|---|

| SPB | Ld (mm): 3,000–8,000 |

| SPC | Ld (mm): 3,000–11,200 |

| 5V/15J | Le (mm): 3,000–8,000 |

| 8V/25J | Le (mm): 3,175–12,500 |

CONTI V TORQUE TEAM ADVANCE Belts in the TYMA CZ Eshop

CONTI V TORQUE TEAM ADVANCE Belts in Action

The Universal Soldier of V-belts – a slightly playful way to describe CONTI V TORQUE TEAM ADVANCE. Let’s take a look at some typical use cases.

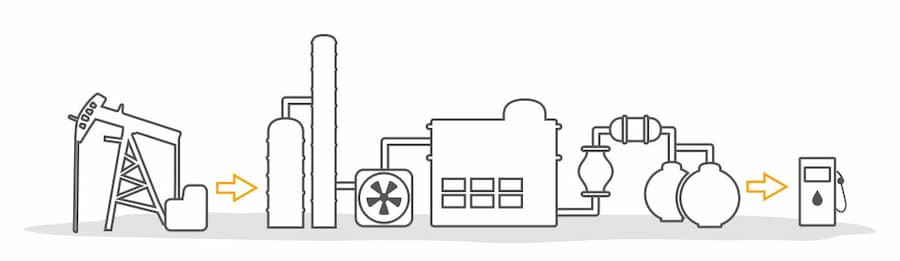

Oil and Gas Industry, Refineries: Pumping and Ventilation

The extraction and processing of raw materials into premium end products are among the most demanding applications.

CONTI V TORQUE TEAM ADVANCE is the ideal choice for pump systems, compressors, and cooling towers in the oil and gas industry. Suitable for heavy-duty operation in harsh environments and at critical stages of the value chain.

Example: Oil Refinery

Once the crude oil has been extracted, the raw material passes through a number of processes on its way to becoming marketable products. These include distillation, refining, desulfurization, blending, and final transport to the end customer. Pump and ventilation systems play an important role throughout these processes.

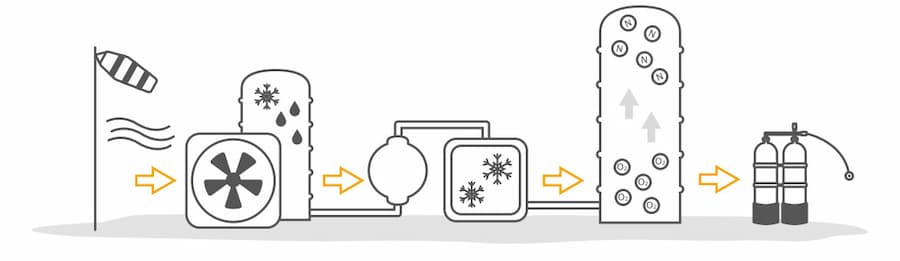

Chemical and Industrial Gas Plants: Pumps and Compressors

In the chemical industry’s complex processes, raw materials are either transformed from natural substances or synthesized into entirely new compounds. Conveying, mixing, and compression systems demand maximum uptime and trouble-free operation.

This is where the qualities of CONTI V TORQUE TEAM ADVANCE banded V-belts really prove their worth.

Example: Oxygen Production

Air separation plants divide atmospheric air into oxygen, nitrogen, and argon. Large intake systems draw in the required volumes of air and compress it. The resulting cooling causes the gases to liquefy, allowing them to be extracted at different boiling points.

Mining Industry: Crushers, Shredders, Screening Machines, and Mud Pumps

Cement production often involves high temperatures or very high levels of dust when sand or gypsum is added. The crushers, mills, and kilns used in these applications require extreme performance day in and day out under exceptionally harsh conditions. Mechanical drive components in particular face constant, extreme stress.

CONTI V TORQUE TEAM ADVANCE is engineered for these environments. Its robust construction allows it to withstand these loads, even when the drive cannot be re-tensioned.

Example: Cement Manufacture

Raw materials for cement are quarried. Crushers reduce the stone to gravel. After homogenization, the mixture is ground to a raw mix and burned in a rotary kiln to form cement clinker. Further ingredients are added to produce finished cement in the mill.

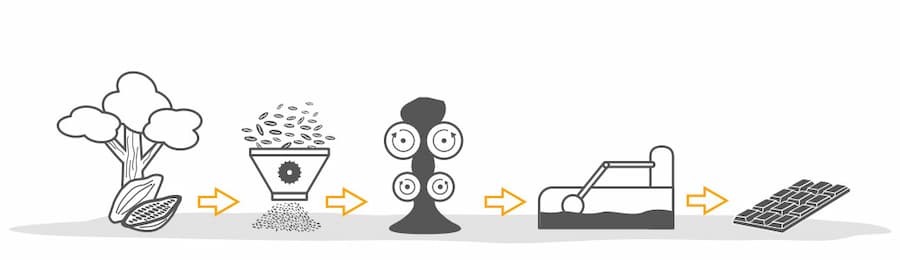

Food Industry: Large Mixers, Blenders, and Mills

Heavy-duty drives with large center distances require particularly tough power transmission belts.

This is where CONTI V TORQUE TEAM ADVANCE comes into play. Its maintenance-free construction ensures reliable operation of large machines in the food industry, where high power inputs are used to grind, roll, and mix natural products.

Example: Chocolate Production

After roasting, cocoa bean shells are cracked and removed, and the cocoa nibs are ground. The cocoa mass is then hydraulically pressed and milled in several stages to produce cocoa powder. Chocolate is created by mixing the dry cocoa mass with cocoa butter, followed by conching.

Wood Industry: Sawmills, Wood Chippers, and Shredders

CONTI V TORQUE TEAM ADVANCE is ideal wherever wood is processed, refined, or machined. From cellulose production to the manufacture of semi-finished and finished products: the tough, durable belt construction provides maximum reliability and machine availability across the entire production process.

Thanks to its universal properties, it can be used in almost all chipping, mixing, conveying and sawing systems.

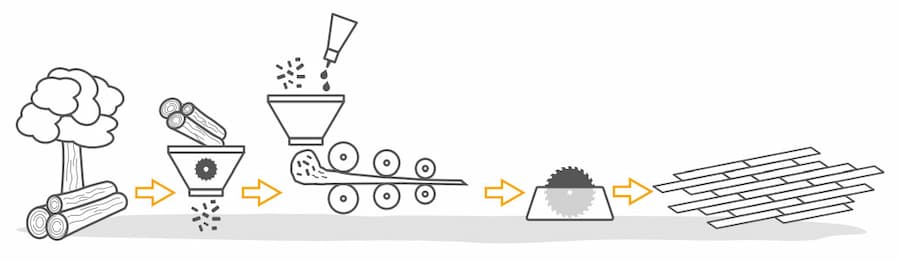

Example: Laminate Production

To produce laminates, trees are felled, debarked and chipped. Cellulose is extracted from the wood chips and formed into a pulp. This pulp is pressed in roller mills, shaped with a surface design, and cut to size.

Paper Industry: Large Mixers and Pumps

In the paper industry, fibers are first extracted and mixed with water. The resulting pulp is then processed into paper or cardboard. Due to its properties, pulp presents an especially aggressive environment for power transmission belts.

The CONTI V TORQUE TEAM ADVANCE’s double jacket protects the elastomer from these environmental influences, allowing the belt to maintain excellent performance throughout a long service life.

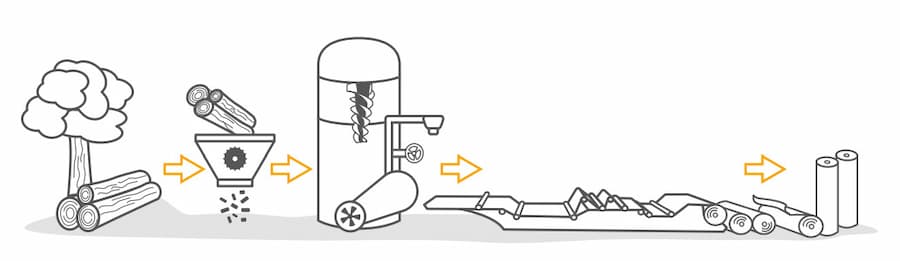

Example: Paper Production

Fibers are extracted from wood and mixed with water, brighteners, and pigments. The pulp is then formed into continuous sheets by papermaking machines, and excess water is removed. The sheets are pressed between rollers, dried, and rolled into large paper reels.

Road Construction: Mobile Crushers, Milling Machines, Asphalt Pavers, and Compactors

In modern road construction, both contractors and operators need durable, efficient machines to meet budget constraints and deadlines. Only with the latest generation of power transmission belts can crushers, planers, pavers, and compactors meet today’s demanding requirements.

In these extreme conditions, CONTI V TORQUE TEAM ADVANCE sets the benchmark for durability and reliability.

Example: Pavement Resurfacing

During resurfacing, natural stone or reclaimed asphalt is milled using cold planers and processed in mobile crushers. Once the substructure is completed, new asphalt is laid by a paver. Rolling and vibrating operations ensure the new pavement meets required load-bearing capacity.

Feeling inspired?