ZIPLINK Special Conveyor Belts

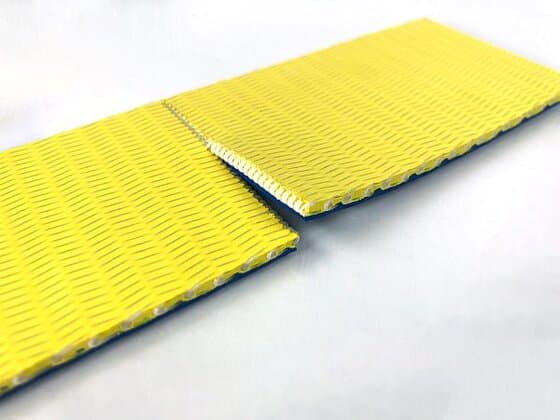

ZIPLINK special conveyor belts represent a breakthrough in belt construction. The base of the belt consists of the top cover material while the bottom part consists of a unique spiral, which can be easily joined to an endless belt of any length without the use of special tools.

The belts have the same structure without a joint along their entire length. Only a part of the belt is replaced during the repair.

Main Types of Belt Materials

The ZIPLINK product range contains more than 30 types of materials. The most common are:

-

COTTON/FELT

The material is resistant to temperatures up to +120 °C.

-

CARBOXYLED NITRILE

The material is very resistant to abrasion and oils and greases. It shows good adhesion in both humid and dry environments. The temperature resistance range is from −18 °C to +121 °C.

-

NITRILE

The material has excellent resistance to oils and greases. It is also resistant to wear and tear. The temperature resistance range is from −18 °C to +121 °C.

-

NATURAL RUBBER

The material shows excellent abrasion resistance and excellent adhesion in both humid and dry environments. The temperature resistance range is from −40 °C to +121 °C.

-

SBR

The material is resistant to abrasion. The temperature resistance range is from −40 °C to +121 °C.

-

SILAM

The material is non-stick and chemically resistant. It is resistant to cold from −54 °C and heat up to +176 °C (or for short periods up to +260 °C).

-

TEFLON

Non-stick material with excellent chemical resistance. It is also resistant to stains, oil and grease. However, it has a low resistance to abrasion and wear and tear. The temperature resistance range is from −50 °C to +82 °C.

Typical Applications

ZIPLINK belts are designed for the transport of material in all branches of industry.

They are used mainly in the food, paper and cardboard, woodworking, tobacco, glass, ceramic, automotive or chemical industries. They are also used in agriculture or in the manufacture of tires and in many other machines and equipment.

Belt Joints

With ZIPLINK technology, the time required to replace a belt and the number of workers required to replace it are reduced by more than half.

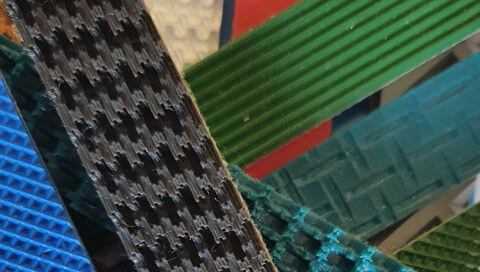

Surface Structures

The surface structure ensures the specific properties of the belt. Applications range from easy separation of the product from the belt to the use of surface adhesion in technological processes or for inclined transport.

The surface structures can be on the top or bottom cover layer. The choice of structure depends on the properties of the transported product.

There are many types of structures in the product range. The most common can be found in the Overview of Standard Surface Profiles (PDF file for download).

Accessories

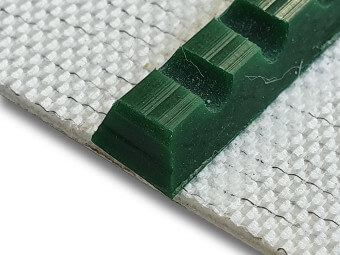

Guides

Guide profiles ensure direct belt guidance and prevent belt movement on the rollers. The result is a smooth guidance without a polygon effect, which is also suitable for higher speeds.

Profiles made of PVC, polyurethane or polyester are welded or glued to the bottom side of the conveyor belt.

The V-profile can also be used as a transverse carrier or side edge for transporting material.

The most common way of guiding the belt is a V-guide.

| Profile Type | Description | Illustration |

|---|---|---|

Full V-Profile |

The smooth, clean design of the wedge is less prone to contamination. |

|

Lightweight V-Profile |

On the bottom side of the belt there is a wedge with pressed teeth, which allow easier bending and thus smaller cylinder diameters than solid wedges. |

|

In addition to the V-profiles, the guide profiles can also be square. However, their use is far from numerous. If you are interested in implementing square guide profiles, please contact us.

Documents for Download

Questions about This Belt Category?

Don’t hesitate to contact us with any questions about products in this category.

Belt Manufacturer Profile

Ammeraal Beltech is a global market leader in the development, manufacturing, and servicing of high-quality, high-performance process and conveyor belts. Its products are used across almost all industries and are supplied to more than 150 countries worldwide.

The company employs more than 3,000 people. Manufacturing takes place in 10 production facilities across Europe, North America, and Asia.

We are an authorized distributor and service partner, operating our own center for the production, assembly, and maintenance of Ammeraal Beltech flat belts and conveyor belts for the region.

Related Articles

ZIPGUIDE Conveyor V-Belts

A modern alternative to standard belts. Greater reliability, longer service life, less maintenance. Based on the ZIPLINK principle.