Chain Identification

Which chain do you have? We have prepared a guide to help you identify your roller or bush chain (drive or conveyor). Markings are often missing on installed or damaged chains.

Follow the steps below. If anything is unclear, please contact us.

Next Steps

- Step 1 – What Chain Design Do We Have?

- Step 2 – What Is the Chain Pitch?

- Step 3 – What Are the Inner Width and Roller Diameter?

- Step 4 – Which Standard Chain Type Is It?

- Step 5 – What Is the Chain Length?

- More Tips for Roller Chain Identification

Need a New Roller Chain?

Buy chains directly from the TYMA CZ Eshop!

Select a Roller Chain or Contact a Specialist.

Related categories:

Sprockets, Tensioners, Chain Guides, Wear Gauges

Step 1

What Chain Design Do We Have?

Roller Chain…

In industry, roller chains are used most frequently. They are typically made of steel and consist of inner and outer plates, pins, bushes and rollers. The bushes are press-fitted into the inner plates, the pins into the outer plates; the rollers rotate freely on the bushes and roll over the sprocket teeth in mesh, thereby minimizing friction and wear.

… or a Bush Chain?

In some smaller sizes you will also encounter bush chains, recognizable by the absence of rollers – their bushes run directly on the sprocket. In the vast majority of cases, however, the chain is a roller chain, so for simplicity we will refer to all chains in this guide as roller chains.

How Many Strands Does the Chain Have?

The most common are…

What Is the Plate Shape?

In most cases you will see…

On some heavy-duty chains you may also encounter reinforced plates. Some types may also have a modified geometry (e.g., a “wider waist”).

The strand count is obvious at a glance. Plate shape usually is, too. The remaining parameters must be measured.

Step 2

What Is the Chain Pitch?

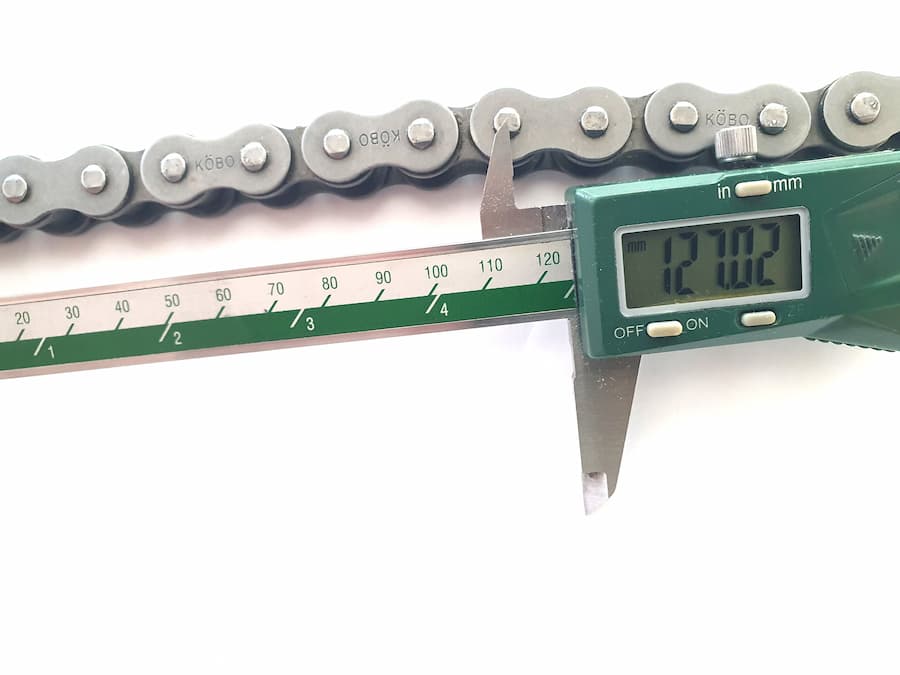

To check whether we are dealing with a standard roller chain, start by measuring the chain pitch.

Divide the measured length by the number of pitches n. In our case we measured across 8 pitches, so divide 127.02 mm by 8. The result is a pitch of 15.8775 mm.

Below you will see that in this particular case we would have obtained a sufficiently accurate value even from a single-pitch measurement, which gave 15.85 mm.

Step 3

What Are the Inner Width and Roller Diameter?

Step 4

Which Standard Chain Type Is It?

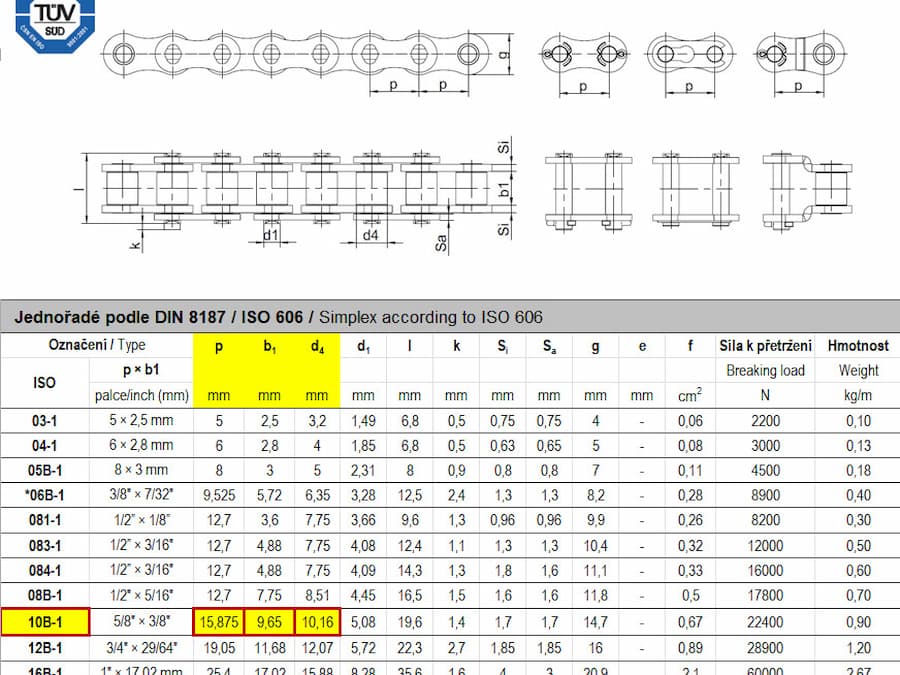

The key question is: Is the chain compliant with ISO 606?

More specifically – does it belong to the European/British B series defined by DIN 8187, or to the American A series according to ANSI B29.1 (formerly ASA), i.e., DIN 8188?

If yes, which type is it? Use the Chain Catalog (pdf, 3.58 MB).

Allow for measurement tolerance, approximately 0.05–0.10 mm. For pitch, also allow for elongation due to wear, expressed in percent (as a guideline: up to 2% acceptable; above 3% critical!).

Dimensions in the standards are derived from inch sizes, so they often do not correspond to whole millimeters. This is because the first roller chains were manufactured in Great Britain in the late 19th century.

Measurement Example

| Dimension | Measured value (mm) | Catalog value (mm) | Catalog value (inch) |

|---|---|---|---|

| Pitch p | 15.878 | 15.875 | 5/8 |

| Inner width b1 | 9.70 | 9.65 | 3/8 |

| Roller diameter d4 | 10.09 | 10.16 | - |

In our example, the measured values match chain type 10B-1. We have therefore identified a European (B-series) simplex chain (single-strand) defined by ISO 606 and DIN 8187.

Step 5

What Is the Chain Length?

Dividing the measured total length of 2,050 mm by the measured pitch 15.878 mm gives, after rounding, the same result as counting all inner and outer links: 129.

To join the chain with a standard straight connecting link, the chain without the link must have an odd number of links – both ends must be inner links. If, however, you need the final number of links to be odd including the link, you must use a crank connecting link (use sparingly, as it reduces the chain’s load rating/service life).

Standard roller chains are supplied in 5 m packs. Some manufacturers include one or two connecting links in the pack. The most common roller chains, especially simplex chains, are also sold by the meter.

More Tips for Roller Chain Identification

Chain Designs

Depending on the application, additional material and design factors can also be important.

In the TYMA chain catalog you will find the following additional type codes:

| Code | Description |

|---|---|

| SP | Roller chain with straight plates |

| ZP | Corrosion-resistant roller chains – zinc-plated |

| NP | Corrosion-resistant roller chains – nickel-plated |

| MF | Maintenance-free roller chains |

| SS | Stainless steel roller chains |

| HP | Roller chains with hollow pins |

| HB | Bush chains with hollow pins |

Some roller chains are produced only with straight plates. This applies to types 06B, 04C and 06C.

The Machine’s Country of Origin Can Help

In Europe the European B-series chains are more common. If the machine is imported from the USA or Japan, it is likely to use an American A-series chain. In all cases, measure and verify the dimensions carefully.

B- and A-series roller chains share the same pitch in some sizes – e.g., 5/8 inch, i.e., 15.875 mm. However, their inner width and roller diameter are different! Mixing them will cause malfunction – the chain simply will not fit. The same applies to sprockets.

When the Dimensions Do Not Match the Catalog

If the chain dimensions differ from those listed for standard roller chains, it is most likely a non-standard type or a modification of a standard type.

In such cases, it is best to contact us or send a specification with the dimensions.

Do Not Need a Complete Chain?

Besides complete chains you can also order the relevant connecting parts:

- Straight connecting link with a cotter pin

- Straight connecting link with a spring clip

- Offset link (half link) – crank connecting link (always with a cotter pin)

- Double offset link

Separate links are also available:

- Outer link (separate)

- Inner link (separate)

Is the Chain Already Too Worn?

You know the chain type but are unsure whether it has reached the end of its service life? Get a chain wear gauge in TYMA CZ Eshop!