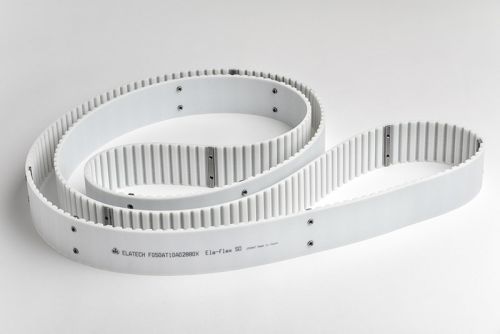

EFT System Connected Polyurethane Conveyor Timing Belts

EFT mechanical fastening system is specially designed for fastening cleats with fixing screws. The system allows the application of profiles of any material (steel, polyamide, POM, wood, etc.) and in any dimension.

The belt tooth is replaced by a metal tooth made of zinc coated or stainless steel with threaded holes. The cleats are then attached to the belt with fixing screws.

EFT connected timing belts are available in two versions: total tooth design (the polyurethane tooth is entirely replaced by a steel tooth) or embedded tooth design (tooth sides remain and prevent metal to metal contact with the pulley).

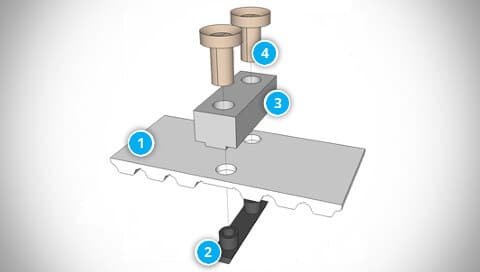

Belt Construction

- EFT belt with ground tooth and holes

- Entered false metal tooth

- Attached carrier

- Fixing screws

Typical Applications

EFT connected timing belts are used in selected industry areas as conveyor timing belts where the cleats are exposed to very high loads, where it is necessary to attach cleats made of different material from the polyurethane belt body or where an easy disassembly and replacement of the cleats is required.

They are most often used in machines in the food, automotive or woodworking industries, in distribution centres, packaging machines and many other devices.

Belt Code Description

Example:

AT10 - 50 - 8900 EFT on every 10th tooth

| Code Part | Description |

|---|---|

| AT |

Profile |

| 10 |

Tooth pitch in mm |

| 50 |

Belt width in mm |

| 8900 |

Belt length in mm |

| EFT on every 10th tooth |

Belt fastening system |

Optional Belt Surface Layers

The choice of the surface layer depends on the type of machine, the ambient temperature, the size of the pulleys, etc. Specifying the surface layer is determined by the material and the thickness of the layer.

| Layer Name | Material | Layer Illustration |

|---|---|---|

| PAZ (NFT) - nylon fabric on teeth Low coefficient of friction |

Nylon |  |

| PAR (NFB) – nylon fabric on back Surface protection |

Nylon |  |

| PAZ + PAR (NFT + NFB) – fabric on teeth and back Low coefficient of friction and surface protection |

Nylon |  |

The fabric on teeth and back can be combined with all other layers. A complete range of belt surface layers

Documents for Download

Questions about This Belt Category?

Don’t hesitate to contact us with any questions about products in this category.

Belt Manufacturer Profile

Elatech S.r.l. is fully dedicated to the research, development, and manufacturing of polyurethane timing belts and flat belts for industrial applications – whether for power transmission, linear motion, lifting, or conveying functions requiring precise synchronous movement. It offers extensive customization options to adapt supplied components to specific applications.

Together with SIT S.p.A. and other companies, Elatech S.r.l. is part of the Scaglia Group. The Group operates in Europe, North America, and Asia, and comprises 7 manufacturing facilities and 6 subsidiaries with more than 1,000 employees. As part of the Group, the individual companies benefit from shared technologies and innovations, providing financial stability and sustainable growth.

We are an authorized distributor of polyurethane timing belts and conveyor belts from Elatech S.r.l., as well as shaft couplings, bushes, sprockets, and pulleys from SIT S.p.A.