ESCODISC DPU Series Couplings

ESCODISC DPU series couplings are all-metal torsionally rigid, backlash-free and maintenance-free shaft couplings. Torque is transmitted by high-strength stainless steel discs.

Shaft Coupling Description

ESCODISC DPU series couplings are of an all-metal, non-lubricated design and are torsionally stiff. The torque is transmitted by means of discs, which are alternatively mounted (on the same bolt circle) to the drive and driven flange of the disc pack assembly.

Disc couplings will in most cases have two flexible elements and a spacer. As all parts are positively connected, the disc coupling ensures good inherent balancing properties and is hence often used at motor speeds without any additional balancing.

The ESCODISC DPU series is built around ESCO Couplings genuine and original disc pack sub assembly design. This design with optimized disc shape and thickness, is factory assembled and secured by shipping screws against damages, minimizes assembly errors, simplifies coupling mounting and guarantees worry free performance, low operating costs as well as long life of the connected equipment.

The total torque capacity and misalignment capacity depend on the disc pack thickness, the disc material, the amount of drive bolts and the free span of the material between the drive bolts. The ESCODISC couplings meet the API 610 and API 671 standards.

Multidisc and flange packed subassembly version with Anti-Spark and Anti-Fly (optional).

The couplings are able to compensate for radial, angular and axial misalignments.

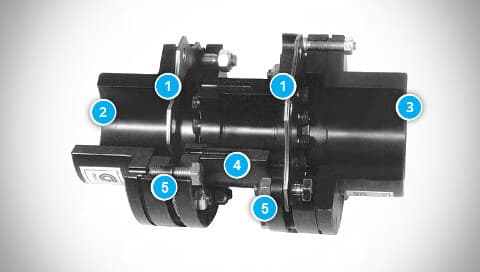

Shaft Coupling Construction

- Set of stainless steel discs with a special surface treatment

- Left hub

- Right hub

- Spacer

- High strength bolts

Typical Applications

ESCODISC DPU series shaft couplings are designed to transmit the highest torques in all industries.

They are used mainly in the drives of compressors, pumps, conveyors, presses, test benches and drives in the chemical, petrochemical, pharmaceutical and food industries.

The disc couplings are available in various series and designs.

Key Features

- Factory-assembled disc packs secured by shipping screws and thus protected against overstressing/damaging

- Positive centring and factory-assembled transmission unit minimizing assembly errors and simplifying coupling mounting

- Fillers avoiding contact between discs hence no fretting corrosion

- Refurbishment of the coupling by fitting two new disc pack sub-assemblies to the existing spacer piece

- Easier and less costly mounting

- Extended life

- Excellent inherent balancing characteristics

- S hub for nominal bores and L hub for larger bores

Documents for Download

Questions about This Shaft Coupling Category?

Don’t hesitate to contact us with any questions about products in this category.

We also provide design and calculation of transmission components, including shaft couplings. In the case of your interest in this service, use the detailed Drive or Coupling Calculation Form.

Shaft Coupling Manufacturer Profile

Thanks to its in-house development, engineering, and manufacturing expertise, ESCO Couplings has become a leading global specialist in high-quality gear and disc couplings for standard as well as highly demanding applications – such as the ICE 3 high-speed trains. Its solutions are used not only in transportation, but also in energy production, mining, the petrochemical industry, construction, and agriculture.

ESCO Couplings SRL is part of the ESCO Group, which is organized into two independent business units – ESCO Couplings and ESCO Transmissions. It operates 4 manufacturing plants and employs more than 200 people in Belgium and other European countries, China, and India. The Group relies on a tightly connected distributor network representing the brand in more than 25 countries worldwide.

We are an authorized distributor of gear and disc couplings from the Belgian company ESCO Couplings SRL.