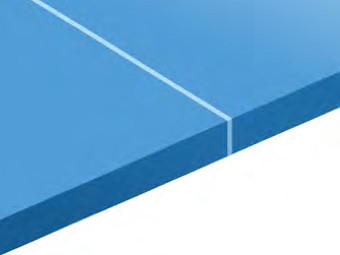

AT5 BEHAbelt Monolithic Conveyor Timing Belts

AT5 BEHAbelt monolithic timing belts are elastic homogeneous belts designed for synchronous movement of the conveyor without the possibility of slipping.

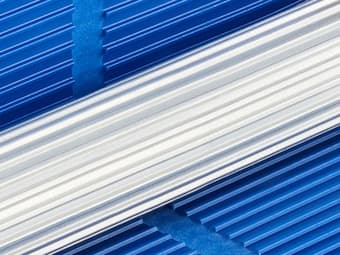

As well as the basic flat monolithic belts, they are made only of polyurethane, they do not contain any textile insert. On the bottom side, they also have a typical AT5 timing belt profile across the entire width or in part. The drive pulley is also toothed and provides a smooth, even operation.

Belts have a monolithic structure that can be easily and perfectly cleaned. They are therefore ideal for use as conveyor belts in the food industry for direct contact with food.

Belt Construction

AT5 BEHAbelt monolithic timing belts are used for transport when the precise synchronous movement is required, i.e. in cases of timing, positioning or precise reversal operations.

They are used mainly in the food industry in the processing of meat, poultry and fish or in the processing of vegetables. They are also used in bakeries, dairies, freezers, but also on many other machines and equipment.

Key Features

- They meet the maximum hygiene requirements for use in direct contact with foodaccording to the HACCP system

- Resistance to microbes, hydrolysis and chemicals

- Low pretension of only 1.5 % (±0.5 %), enables easy installation and reduces bearing load

- Maximum belt width up to 700 mm

- High flexibility for the use of the smallest pulley diameters – starting with a diameter of 18 mm

- A wide selection of different surface structures for different applications

Belt Demonstration Video

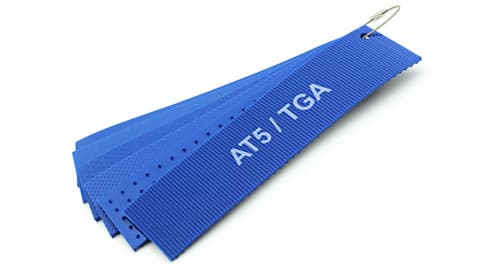

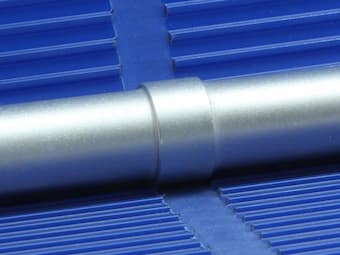

Belt Joints

| Joint Type | Description | Illustration |

|---|---|---|

Butt Weld |

BEHAbelt monolithic belts are joined usually by butt welding. The belt is cut straight at both ends and then joined into an endless belt by heat on the welding machine. |

|

Surface Structures

AT5 BEHAbelt monolithic belts have a perfectly homogeneous structure, which can be smooth or structured depending on the type of application.

All available surface structures are presented in the catalog.

Belt Drive and Guidance Design Types

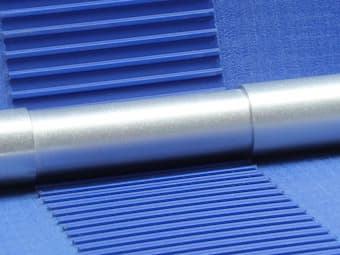

Belt with Center Guide

The monolithic belt does not have teeth in the central part, but a flat central guide groove.

| Description | Illustration | |

|---|---|---|

| Drive | The drive pulley is completely toothed – the guide is provided on the side of the guide pulley. |  |

| Deflection | The driven pulley has a fitting in the central part that ensures the guiding of the belts. |  |

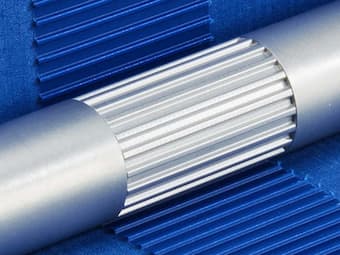

Belt with Central Teeth and Side Guide

The monolithic belt has teeth in the middle part of the teeth and the sides are like a flat belt.

| Description | Illustration | |

|---|---|---|

| Drive | The drive pulley has a central toothing, into which the toothed part of the belt fits – the guide is secured on the side of the guide pulley. |  |

| Deflection | The driven pulley has a smooth fitting in the central part that ensures the guiding of the belts. |  |

Documents for Download

Questions about This Belt Category?

Don’t hesitate to contact us with any questions about products in this category.

Belt Manufacturer Profile

BEHA Innovation GmbH is a German company with a global presence, including a subsidiary in the USA and an extensive distribution network. The manufacturing program of BEHA Innovation GmbH, marketed under the BEHAbelt brand, is based on numerous innovations and proprietary patented solutions.

The company manufactures a complete range of polyurethane and polyester belt profiles for conveying and power transmission applications, conveyor belts and related accessories, as well as welding machines and assembly tools designed for joining plastic belts directly in place.

We are an authorized distributor of thermoplastic belt profiles, belts, and welding equipment from BEHA Innovation GmbH.