Polyurethane Welded Timing Belts

Welded timing belts are polyurethane endless conveyor timing belts manufactured from standard open-ended belts. They are joined under heat on special machines.

Open-ended belts with steel, aramid or stainless steel tensile fibers are prepared to the required size, where a "V"-shaped joint with fingers is cut at both ends, and after being inserted into a precise mold, is joined at a given temperature into an endless belt.

Various surface layers and attachments can be welded or glued on the belts.

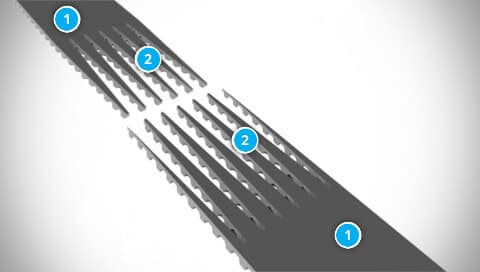

Belts Construction

- Open-ended polyurethane belt

- Belt cut and ready for welding

Belts Fields of Use

Polyurethane welded timing belts are used in all areas of industry as transport timing belts, in linear drives, positioning and lifting devices.

They are most commonly used in conveyors in the glass, ceramic, food, automotive or woodworking industries, in distribution centres, in packaging machines and many other devices.

Belts Characteristics

- High transmitted power and long service life

- Resistant to oil, petrol, benzene, UV radiation and ozone

- Abrasion-resistant

- Maintenance-free

- Temperature range, depending on application, from −30 °C to +80 °C

Belts Code Description

Example:

T10 - 50 - 8920 V + Linatex 2.0 mm

| Code Part | Description |

|---|---|

| TTrapezoidal/Trapezprofil The T profile is a trapezoidal standard profile in a metric pitch for conventional timing belt applications. The tooth geometry allows a play-free belt/sprocket pairing that results in unsurpassed precision. |

Profile |

| 10 |

Toth pitch in mm |

| 50 |

Belt width in mm |

| 8920 |

Belt length in mm |

| V |

Welded |

| Linatex 2.0 mm |

Surface layer |

Notice

Welded polyurethane toothed timing belts are produced in many profiles.

According to the profile, the minimum length is about 700 mm, the maximum length is not limited.

Optional Belt Surface Layers

The choice of the surface layer depends on the type of machine, the ambient temperature, the size of the pulleys, etc. Specifying the surface layer is determined by the material and the thickness of the layer.

| Layer Name | Material | Layer Illustration |

|---|---|---|

| PAZPolyAmid Zahne – Nylon Fabric on Teeth. Thus sometimes also mentioned as NFT. (NFTNylon Fabric on Teeth. Also mentioned as PAZ – PolyAmid Zahne.) - nylon fabric on teeth Low coefficient of friction |

Nylon |  |

| PARPolyAmid Rücken – Nylon Fabric on Back. Thus sometimes also mentioned as NFB. (NFBNylon Fabric on Back. Also mentioned as PAR – PolyAmid Rücken.) - nylon fabric on back Surface protection |

Nylon |  |

| PAZPolyAmid Zahne – Nylon Fabric on Teeth. Thus sometimes also mentioned as NFT. + PARPolyAmid Rücken – Nylon Fabric on Back. Thus sometimes also mentioned as NFB. (NFTNylon Fabric on Teeth. Also mentioned as PAZ – PolyAmid Zahne. + NFBNylon Fabric on Back. Also mentioned as PAR – PolyAmid Rücken.) - fabric on teeth and back Low coefficient of friction and surface protection |

Nylon |  |

The fabric on teeth and back can be combined with all other layers. A complete range of belt surface layers

Documents for Download

Dimensions and Parameters of Polyurethane Joined Endless Timing Belts

TYMA CZ Data Sheets

Czech and English (PDF 196.24 kB)

Question about the Belts Category

Do not hesitate to contact us with any questions about products in this category.